These slush ice cooling systems processes up to 1,200 boxes per house by feeding open boxes continually beneath the injection nozzle. That means that 2,000 boxes per hour can be realized by doubling the system. Uses one 10HP, 3 phase, 230/460 volt motor to drive the entire system. Electrical circuitry has been strategically designed away from ice and water area for user safety. Conveyor feeds boxes at user selected rates. Operator controlled start and stop controls allows for individual box icing. These systems are ideally recessed below floor level to minimized ice and water loss. Skid mounted about the floor systems are also available. Maintains a uniform ice slurry throughout the system preventing freezing up. A high-volume 8” pump easily moves the ice particles without plugging.

The systems provide fast efficient operation with up to 2,000 boxes per hour capacity. Both open box and pallet icing models (shown below) are available in a size to fit your needs. Combine snow ice, water and you have “slush” ice. When injected into a box of produce this slush liquid ice surrounds the vegetables within, filling any open spaces. The water then drains through holes in the box leaving behind instantly cooled vegetables blanketed in snow.

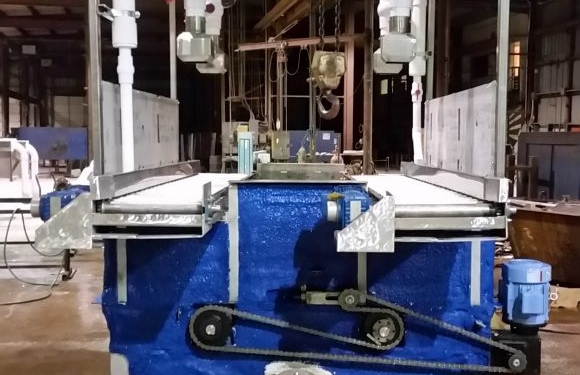

SEMCO/SEMCOLD LLC Manufacturing has designed a variety of Slush Ice systems called its “Sno Pac” line. The systems provide fast efficient operation with up to 2,000 boxes per hour capacity. Both open box and pallet icing models (shown below) are available in a size to fit your needs.

Both systems employ many design features insuring their dependable long life even in the most demanding operations. Some of these features include a rugged agitation system to maintain the ice particles suspended in the water preventing freeze-ups. Especially high volume pumps move the slush mixture without plugging. The system works equally well using block, cube, fragmented or flake ice. The system can be designed to work with your existing ice sources or can provide an ice plant for this system’s use as well as all your other ice needs.

Unlike top icing which can trap heat in vegetables, SEMCO/SEMCOLD LLC’s “Sno Pac” Slush Ice System provides total heat removal and instantly penetrates produce from top to bottom for thorough cooling while leaving a blanket of snow behind.

Excellent for:

- Broccoli

- Sweet corn

- Leafy Greens

- Melons

- Green onions

- and many more!

This system processes up to 1,200 boxes per house by feeding open boxes continually beneath the injection nozzle. That means that 2,000 boxes per hour can be realized by doubling the system. Uses one 10HP, 3 phase, 230/460 volt motor to drive the entire system. Electrical circuitry has been strategically designed away from ice and water area for user safety. Conveyor feeds boxes at user selected rates. Operator controlled start and stop controls allows for individual box icing. This system is ideally recessed below floor level to minimized ice and water loss. Skid mounted about the floor systems are also available. Maintains a uniform ice slurry throughout the system preventing freezing up. A high-volume 8” pump easily moves the ice particles without plugging.

Standard Models

- High capacity continuous flow system

- Efficient hydraulic power

- Hydraulic power PVC roller conveyor

- Single tank mixing and overflow recapture system

- Sloped drain area

- Hydraulic powered agitation system

- Heavy-duty slush ice pump

Unlike top icing which can trap heat in vegetables, SEMCO/SEMCOLD LLC’s “Sno Pac” Customizable Slush Ice System provides total heat removal. Slush ice instantly penetrates produce from top to bottom for thorough cooling leaving a blanket of snow behind.

SP-1200 “Sno-Pac” 1,200 Gallon Capacity Mixing Tank

Complete with drain tank, agitator system, 8” ice pump, 4” PVC distributed line, 4” ice injector nozzle, powered roller conveyor and 10 HP hydraulic power units with plumbing and control valves for systems. Capacity up to 1200 boxes/hour

SP-500 “Sno-Pac, Jr” 500 Gallon Capacity Mixing Tank

Complete with drain tank, agitator system, 5” ice pump, 3” PVC distribution line, 3” ice injector nozzle, powered roller conveyor and 7.5 HP hydraulic power unit with plumbing and control valves for system. Capacity up to 750 – 1000 boxes/hour

PI-48 “Sno-Pac” Pallet Icer 1,500 Gallon Capacity Mixing Tank

Complete with variable speed pallet conveyor, drain tank, agitator system, 8” ice ice pump, two 3” distribution lines, hose, and 2” hand holes for injecting ice into hand holes of palletized field packed vegetables, and 15 HP hydraulic power unit. Capacity up to 700 boxes/hour

PI-36 “Sno-Pac” Pallet Icer Skid Mounted 1,500 Gallon Capacity Mixing Tank

Complete with static icing grid over mixing tank for two pallets 8” 15 HP slush pump, agitator system, and two hand probes for icing field packed vegetables.

PI-24 Skid Mounted 1,200 Gallon Capacity Mixing Tank

Same as PI-36, but with 1200 gallon mixing tank, single probe, and room for icing one pallet at a time.

With a wide range of systems, we provide the help you need

SEMCO/SEMCOLD LLC remains totally committed to providing our customers with the highest quality equipment & services possible. We welcome the opportunity to quote on your projects and help find the financial solution just for you with our recommended LEAF Leasing company.

SEMCO/SEMCOLD LLC’s slush ice systems are designed to provide reliable and efficient cooling solutions for industries such as seafood packing, produce preservation, and food processing. With customizable features, robust construction, and precision engineering, our slush ice systems ensure consistent cooling performance, making them an essential tool for businesses requiring high-quality temperature control.

Interested in enhancing your cooling operations? Explore related equipment like our Ice Storage Bins for large-capacity ice management or check out our Hydrochillers for advanced cooling technology. Click through to discover how SEMCO’s complete line of equipment can optimize your production and storage processes.