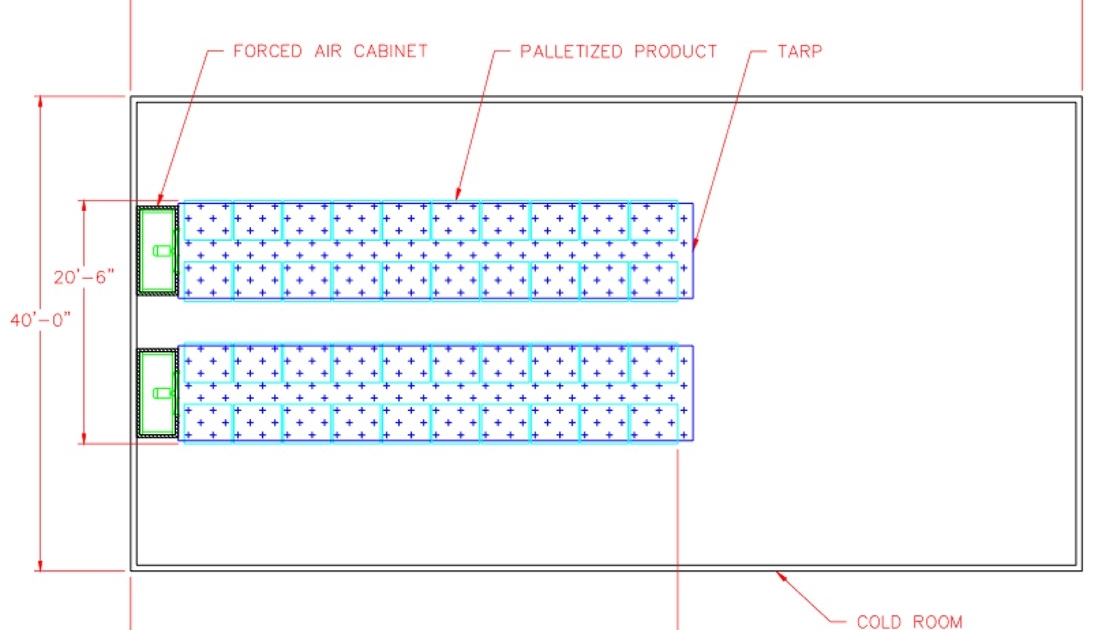

Forced air cooling goes head to head with vacuum cooling efficiency. One single forced air cooling cabinet can cool down up to 20 palletized produce. This works by having the unit inside your cold room and once all palletized produce is aligned and covered with its tarp; once switched on it will then blast the pallets with the cold rooms ambient temperature. The forced cold air then travels down the lane as a tunnel effect, going through every crevice of product and quickly begins to chill down its contents.

Key Benefis

- Uses your cold-room as the cooling base temperature.

- Takes no water unless you want a mist feature.

- No water on the product.

- Cools up to 20 gaylords at a time. About 3 to 4 hours from 32C(90F) to cold-room temperature.

- Tarp cover – Rollover tarp.

- Self-Contained

Efficient and Reliable Cooling with Forced Air Systems

SEMCO/SEMCOLD LLC’s Forced Air Cooling Systems offer a highly efficient and cost-effective solution for rapidly chilling large quantities of produce. Designed to work seamlessly within your existing cold room, this system provides consistent cooling performance while preserving the quality of your products.

Smart Design, Easy Integration

- Self-Contained System: No additional infrastructure required.

- Tarp Cover with Roll-Over Design: Simplifies setup and operation.

- Dry Cooling Process: No water contact unless a misting feature is added.

- Flexible Configuration: Fits directly into your cold room for seamless integration.

High-Capacity Cooling for Maximum Efficiency

With the ability to cool up to 20 palletized products or gaylords in a single cycle, forced air cooling delivers unmatched throughput. The system utilizes your cold room’s ambient temperature to blast chilled air through every crevice of the aligned produce, ensuring even and thorough cooling in just 3 to 4 hours—bringing temperatures down from 32°C (90°F) to the cold room baseline.

Why Choose Forced Air Cooling?

- Efficient Cooling: Quickly chills products without requiring additional water.

- Preserves Product Quality: No excess moisture ensures produce stays fresh and intact.

- Cost-Effective Solution: Uses your cold room as the cooling base, reducing energy consumption.

- High Capacity: Perfect for large-scale operations with heavy cooling needs.

SEMCO/SEMCOLD LLC’s forced-air cooling systems provide fast, energy-efficient solutions for cooling produce, fruits, and vegetables. These systems are designed for precision and reliability, ensuring your products stay fresh longer while maintaining top quality. With customizable features and robust construction, our forced-air cooling systems are the perfect fit for agricultural and industrial applications.

Need help with financing? Explore LEAF Leasing financing options to make your investment easier and get the equipment you need today. Want to learn more about our full range of solutions? Check out our Vacuum Cooling Systems or Hydrochillers to discover how SEMCO can meet all your cooling needs.