The entertainment and movie industry is all about creating authenticity. Often times that involves reproducing an environment that requires ice, snow, or other cold, wintery themes. It could be a movie that takes place during Christmas, a scene that focuses on winter sports like skiing or snowboarding, or perhaps the characters are merely supposed to deliver their performance over a backdrop of snow or ice. However, just because the story calls for snow and ice doesn’t mean that Mother Nature will cooperate. That’s where industrial ice crushers and blowers come into play.

Saving Money on Location Costs

Big budget movies may have the funds available to fly the entire cast and crew off to some exotic wintery vista; however, for smaller productions or brief, fleeting scenes it may simply not be in the budget. Industrial ice crushers and ice blowers can come to the rescue by quickly providing a man-made set that rivals the real thing without pricey travel and relocation costs.

Providing Authentic Scenery and Landscape

Just because the ice and snow produced by industrial equipment is manmade that doesn’t make it artificial. Industrial ice crushers and ice blowers create actual flaked snow and ice that will look and behave just like the kind that falls from the clouds. This ensures that the scenery looks authentic and behaves appropriately when it is interacted with by actors or props. This typically provides a much better option than artificial substances that may not melt, clump, or ball as they are supposed to.

Creating Great Special Effects

Some scenes may call for special effects such as a snowy gust of wind or a bank of snow blowing out as something crashes into it. Industrial blowers are ideal for this type of special effect since they can deliver impressive blowing force and distance and help capture the effect perfectly. They can also be used for a variety of other great special effects as needed.

Enhancing Safety

Out in nature snow and ice can be very unpredictable and dangerous. Actors or even professional stuntmen can easily be harmed by hidden rocks, uneven layers or snow, or unexpected clumps. By creating the snow and ice with industrial equipment such factors can be taken into consideration and the entire scene can be optimized for safety.

Adding Control

Even if a movie can be filmed in a wintery paradise, there is certainly no guarantee that the natural environment will cooperate with the production schedule. Unseasonably warm days still occur and just because snow was expected doesn’t mean it will actual form. Industrial ice crushers and ice blowers can add that extra degree of control that will keep production on schedule and ensure that everything is just as it should be in terms of ice and snow.

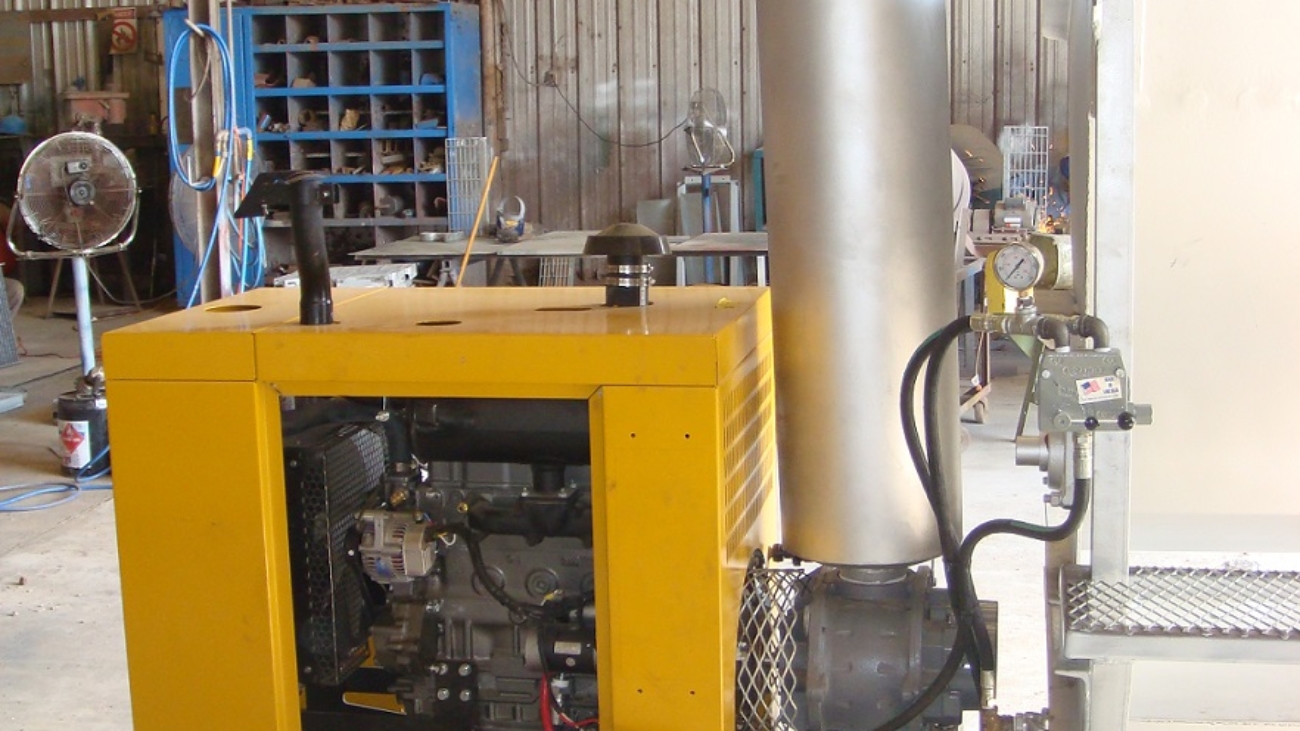

SEMCO/SEMCOLD LLC designs and manufactures high quality, dependable industrial ice crushers and ice blowers that are ideal for use in the entertainment industry. Our specialists will work closely with you to create a system that perfectly fits your needs.